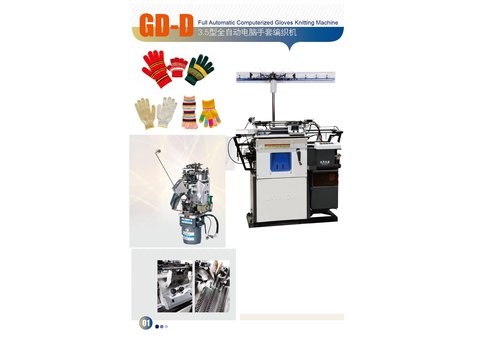

Fully Automatic Gloves Kniting Machine

Fully Automatic Gloves Kniting Machine Specification

- Input Power

- 220 Volt (V)

- Application

- For Safety Industry

- Function

- Fully Automatic

- Material

- Metal

- Color

- White

- Weight

- 250 Kilograms (kg)

Fully Automatic Gloves Kniting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 10-15 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Box.

- Main Domestic Market

- All India

About Fully Automatic Gloves Kniting Machine

As a growth oriented manufacturer, supplier, exporter and trader, we have carved a niche in the domain of Full Automatic Gloves Knitting Machine in the market. This technically advanced Full Automatic Gloves Knitting Machine is featured with computer program controlled mechanism, LCD working platform, powerful motor, specially designed needle bed, multicolor mix color device and sinker device. Developed by utilizing superior quality raw materials, this knitting machine has gone through several quality checking procedures to prove its defect free nature before its delivery in the market.

Efficient and Reliable Production

This Fully Automatic Gloves Knitting Machine accelerates glove production processes without sacrificing quality. Ideal for businesses operating in the safety industry, the machines automated features ensure every batch meets stringent standards. Automation allows for streamlined workflow, reducing errors and maximizing output, making it a valuable choice for manufacturers and suppliers.

Robust Construction and Versatile Application

Crafted with high-grade metal, the machine withstands extensive use while maintaining performance. Its versatility makes it suitable for distributors, traders, and wholesalers catering to various safety requirements. The sturdy build paired with fully automatic controls translates into a worry-free, low-maintenance addition to any industrial setting.

FAQs of Fully Automatic Gloves Kniting Machine:

Q: How does the Fully Automatic Gloves Knitting Machine operate?

A: The machine executes glove knitting functions automatically, utilizing a programmed system to weave gloves efficiently with minimal manual intervention. Operators simply set up the parameters, and the device manages production, quality, and speed.Q: What benefits does this machine offer for the safety industry?

A: By automating glove manufacturing, the machine ensures consistent quality, increases productivity, and reduces labor costs. Its reliability plays a crucial role in meeting the safety industrys stringent standards for protective gloves.Q: When is it ideal to use this gloves knitting machine?

A: The machine is best employed when large quantities of safety gloves are required, particularly for organizations seeking efficiency and scale in production, such as manufacturers, suppliers, and exporters.Q: Where can this machine be installed?

A: Suitable for factories, industrial plants, and large workshops throughout India, the machines robust construction supports prolonged usage in demanding environments catering to distribution and wholesale.Q: What is the process for producing gloves with this machine?

A: Operators feed raw material into the machine, configure the necessary settings, and initiate the automated knitting process. The machine handles all stages of production, delivering finished safety gloves ready for distribution.Q: How should the machine be used for optimal performance?

A: Ensure the machine is correctly installed on a stable surface, supplied with 220 Volt power, and maintained regularly. Proper setup and routine checks result in consistent output and extend the lifespan of the unit.Q: What advantage does the metal construction provide?

A: The metal body enhances durability and resilience, allowing the machine to sustain continuous operation in industrial environments. This robust build contributes to minimal downtime and reliable performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gloves Knitting Machines Category

JOMDA Glove Knitting Machine

Price Range 205000.00 - 225000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Metal

Function : Fully Automatic

Color : White

Gloves Knitting machine

Price Range 150000.00 - 180000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Metal

Function : Fully Automatic

Color : White

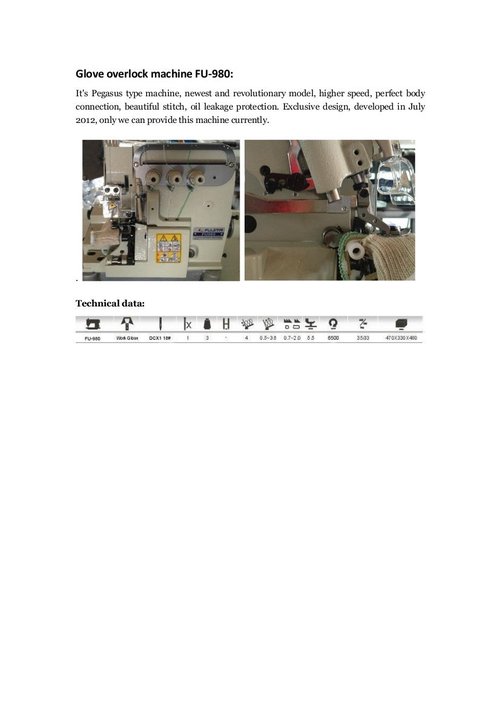

Fujita Gloves Overlock Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Function : Semi Automatic

Color : Off White

Glove Overlock Machine

Price 40000 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Metal

Function : Semi Automatic

Color : Off White

We have also started dealing in international market and also dealing in bulk order quantity.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese